warp (wôrp) v. warped, warp·ing, warps v.tr. 1. To turn or twist (wood, for example) out of shape; deform. 2. To alter from a normal, proper, or healthy state; twist or

WARP TECHNOLOGIES, INC. Established 1988. Holly Springs, North Carolina, USA. Multiple spinning/extrusion lines for processing fine denier polyester for automotive, industrial and apparel applications

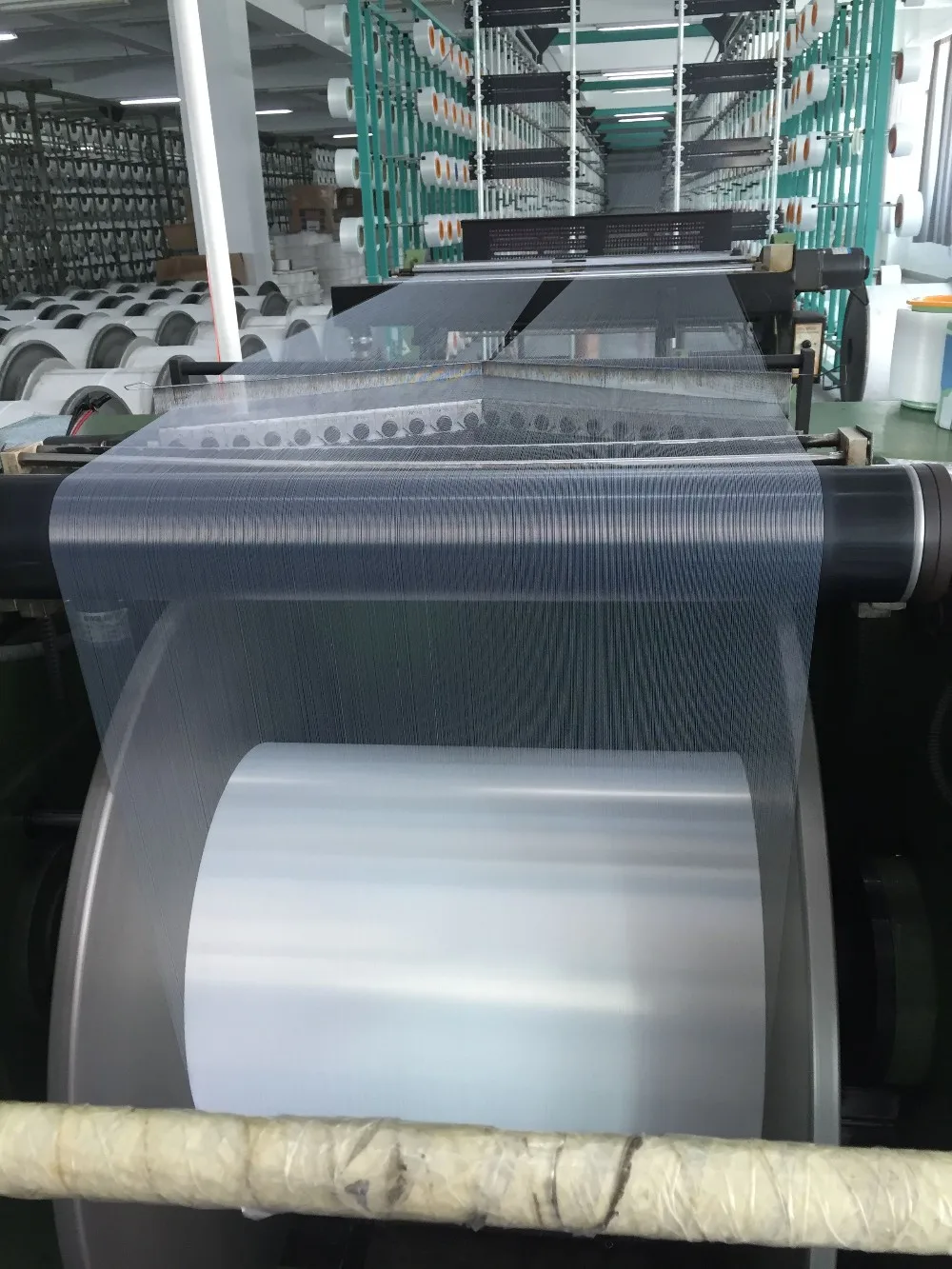

WARP PROCESSING CO., INC. Established 1982 . Exeter, Pennsylvania, USA. Large conventional warping operation with diverse warping equipment. Monofilament and multifilament polyester, nylon 6 and nylon 6,6 yarns

Physical and Chemical Properties Nylon Fabrics Composition: The nylons are polyamides with recurring amide groups. They contain carbon, oxygen, nitrogen and hydrogen elements.

Terms & Definitions. Textile people really do speak their own language. And besides the terms used in spinning, we also need to understand the terms fiber producers use.

Nylon is a generic designation for a family of synthetic polymers, based on aliphatic or semi-aromatic polyamides.Nylon is a thermoplastic silky material that can be melt-processed into fibers, films or shapes.

Click here to download MSDS. NYLON 6,6 FABRICS. Nylon 6,6 is a very versatile fiber. Fabrics composed of nylon 6,6 fiber offer the following characteristics:

Vertical Warping Mill/Reel. Leclerc Warping Mills are the fastest way of making chained warps with a variation of threads and colours. The cross sections that hold the pegs may be adjusted up or down depending on the warp length.

We’ve broken down some helpful information about polypropylene, nylon, and polyester, so you can be better informed about choosing promotional products.

The warp is the set of yarns or other elements stretched in place on a loom before the weft is introduced during the weaving process. It is regarded as the longitudinal set in a finished fabric with two or more sets of elements.